In the world of electronics, the terms solder and desolder are frequently encountered, yet they represent two distinct processes that are fundamental to the assembly and repair of electronic components. Understanding the differences between these two processes is essential for anyone involved in electronics, whether you're a hobbyist, a technician, or an engineer. This article delves into the nuances of soldering and desoldering, exploring their definitions, techniques, tools, and applications.

What is Soldering?

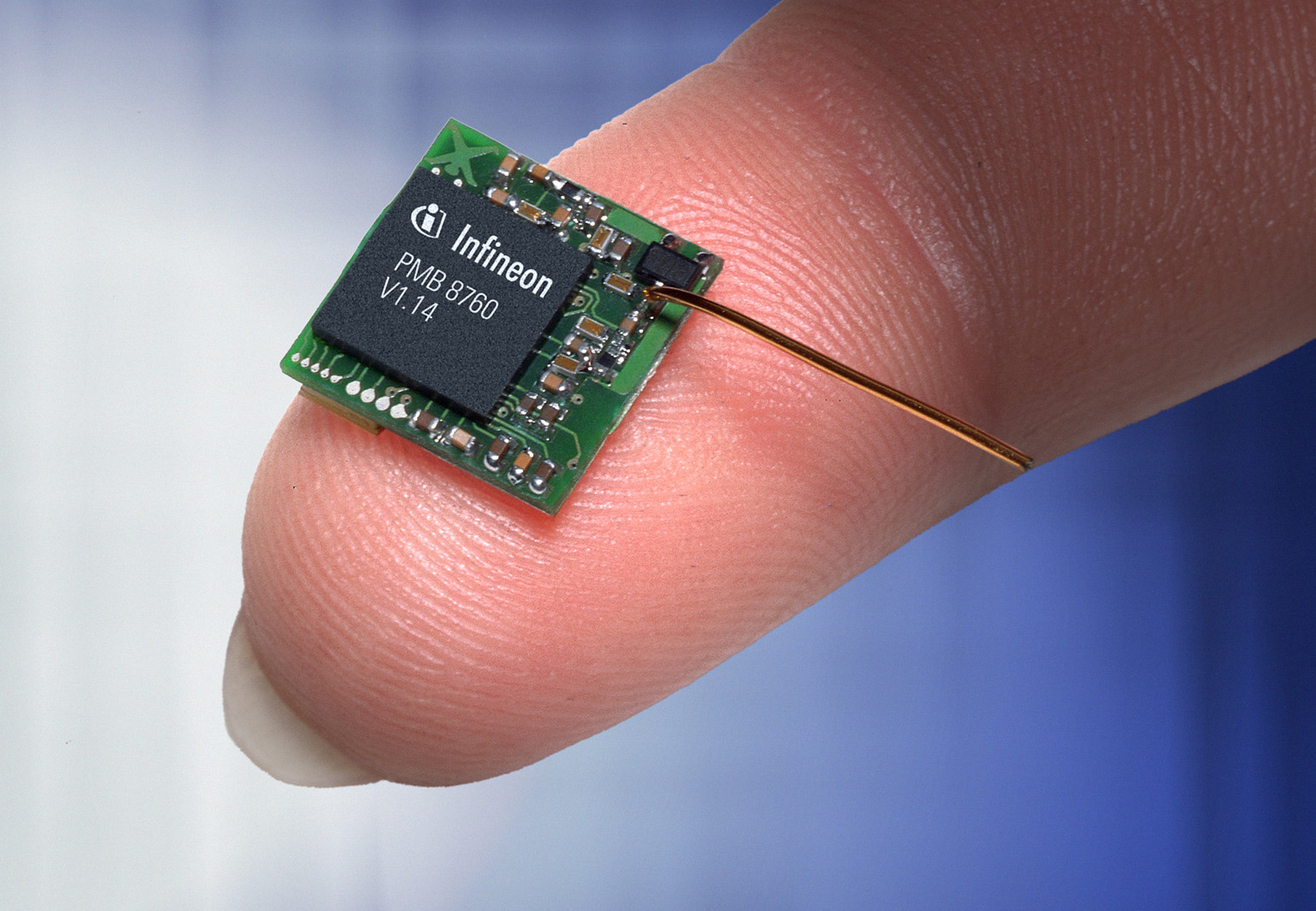

Soldering is the process of joining two or more electronic components together by melting solder, a fusible metal alloy, to create a permanent electrical connection. This process is critical in the assembly of circuit boards, where components such as resistors, capacitors, and integrated circuits are attached to a substrate.

The Soldering Process

- Preparation: Before soldering, the surfaces of the components and the PCB (Printed Circuit Board) must be cleaned to ensure a good connection. Oxidation or contaminants can prevent solder from adhering properly.

- Heating: A soldering iron, which typically reaches temperatures between 350°C to 400°C (662°F to 752°F), is used to heat the joint where the solder will be applied.

- Applying Solder: Once the joint is heated, solder is introduced to the joint, where it melts and flows into the connection, creating a bond as it cools and solidifies.

- Cooling: After the solder has been applied, the joint is allowed to cool naturally, forming a strong electrical and mechanical connection.

Types of Solder

There are various types of solder, including:

- Lead-based Solder: Traditionally used due to its excellent electrical conductivity and ease of use. However, due to health and environmental concerns, its use has been restricted in many applications.

- Lead-free Solder: Composed of tin, copper, and other metals, this type is now more common in consumer electronics and complies with regulations like RoHS (Restriction of Hazardous Substances).

What is Desoldering?

Desoldering, on the other hand, is the process of removing solder to detach components from a circuit board. This is often necessary for repairs, upgrades, or component replacements.

The Desoldering Process

- Preparation: Similar to soldering, the area around the joint must be prepared. This may involve cleaning the joint and ensuring that the workspace is organized.

- Heating: A desoldering tool, such as a soldering iron or a desoldering pump, is used to heat the solder joint.

- Removing Solder: Once the solder is melted, it can be removed using one of several methods:

- Desoldering Pump: A mechanical device that creates a vacuum to suck up the molten solder.

- Desoldering Braid: A copper braid that absorbs solder when heated, allowing for clean removal.

- Soldering Iron: In some cases, the solder can simply be wiped away with a soldering iron if the joint is accessible.

- Cleaning: After desoldering, the area should be cleaned to remove any residual solder or flux, ensuring that the PCB is ready for new components.

Key Differences Between Solder and Desolder

- Purpose: The primary difference lies in their purpose. Soldering is about creating connections, while desoldering focuses on breaking those connections.

- Tools Used: Soldering typically requires a soldering iron and solder, whereas desoldering may involve additional tools like desoldering pumps or braid.

- Skill Level: While both processes require skill, desoldering can be more challenging due to the need for precision to avoid damaging the PCB or surrounding components.

- Heat Management: Soldering involves applying heat to create a bond, while desoldering requires careful heat application to avoid overheating and damaging the components or the board.

Practical Applications

Understanding the difference between soldering and desoldering is crucial in various applications:

- Repair and Maintenance: Technicians often need to desolder components for repairs, making it essential to master this skill alongside soldering.

- Prototyping: Engineers frequently solder and desolder components during the prototyping phase of product development, requiring proficiency in both techniques.

- Hobby Electronics: For hobbyists, knowing how to solder and desolder can significantly enhance their ability to build and modify electronic projects.

Conclusion

In conclusion, while soldering and desoldering are interconnected processes in the realm of electronics, they serve fundamentally different purposes. Mastery of both techniques is essential for anyone involved in electronics, from hobbyists to professionals. By understanding the intricacies of each process, practitioners can ensure reliable connections and successful repairs, ultimately leading to better performance and longevity of electronic devices. Whether you are soldering a new component onto a PCB or desoldering an old one for replacement, the skills you develop will be invaluable in your electronic endeavors.