In the digital age, electronic chips, also known as integrated circuits (ICs), are the lifeblood of our technology-driven world. From smartphones and computers to cars and home appliances, these tiny powerhouses are the driving force behind the functionality of our devices. But what exactly makes electronic chips? This article delves into the intricate process of chip creation, the materials used, and the evolving technologies shaping the future of this industry.

The Birth of an Electronic Chip: From Sand to Silicon

The journey of an electronic chip begins with the most abundant material on earth's crust - sand. Specifically, it's the high-quality quartz sand, rich in silicon dioxide, that is the primary raw material. Through a series of chemical reactions and purification processes, this sand is transformed into ultra-pure silicon, the fundamental building block of electronic chips.

The Silicon Wafer: A Canvas for Circuits

The purified silicon is then melted and formed into a cylindrical silicon ingot, which is sliced into thin, flat wafers. These wafers serve as the canvas onto which the electronic circuits are etched. The process of etching, known as photolithography, involves multiple steps of coating the wafer with a light-sensitive material, exposing it to ultraviolet light through a patterned mask, and then using chemicals to etch away the exposed areas. This process is repeated multiple times to create the complex multi-layered circuits that make up an electronic chip.

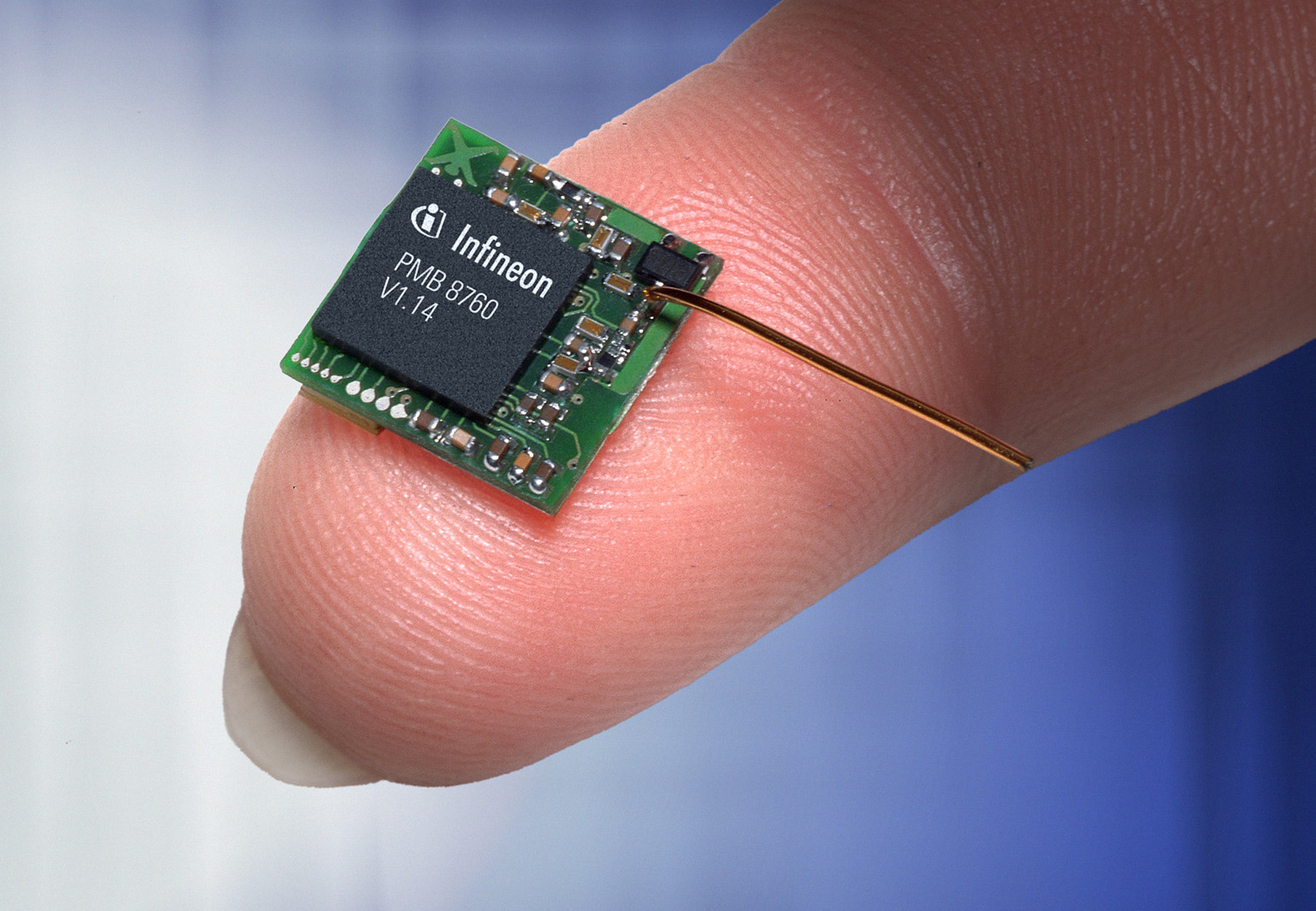

The Power of Miniaturization: Moore's Law in Action

One of the key factors that make electronic chips so powerful is their miniaturization. According to Moore's Law, the number of transistors on a chip doubles approximately every two years, leading to an exponential increase in computing power. This has been made possible through advancements in photolithography, allowing for ever-smaller features to be etched onto the silicon wafer.

The Future of Electronic Chips: Beyond Silicon

While silicon has been the material of choice for electronic chips for decades, the industry is now exploring new materials and technologies to overcome the physical limitations of silicon and continue the trend of miniaturization. Materials like graphene and technologies like quantum computing hold the promise of creating chips that are even smaller, faster, and more energy-efficient than their silicon counterparts.

In conclusion, the making of electronic chips is a complex process that involves the transformation of sand into silicon, the etching of intricate circuits onto silicon wafers, and the relentless drive towards miniaturization. As we look to the future, the evolution of materials and technologies will continue to shape the landscape of electronic chip creation, powering our digital world in ways we can only begin to imagine.