In the realm of electrical engineering, contactors play a pivotal role in controlling and managing the flow of electricity. These versatile devices serve as the gatekeepers of power, enabling the smooth operation of various electrical systems. In this blog post, we will delve into the intricacies of contactors, uncovering their main functions and shedding light on their significance in different industries.

- Contactor Basics:

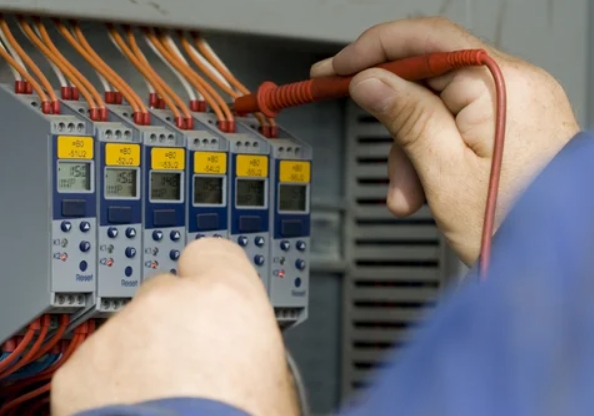

Before we dive into the main functions, let's first understand what a contactor is. A contactor is an electromechanical switch that allows or interrupts the flow of electrical current to a load. It consists of a coil, contacts, and an enclosure. The coil generates a magnetic field when energized, which attracts the contacts, closing the circuit and allowing current to flow. - Control and Protection:

One of the primary functions of contactors is to control and protect electrical systems. By acting as a remote-controlled switch, contactors enable the safe and efficient operation of motors, lighting systems, heating elements, and other electrical devices. They provide a reliable means of starting, stopping, and reversing the flow of electricity, ensuring smooth and controlled functioning. - Overload Protection:

Contactors also serve as guardians against electrical overload. In industrial settings, heavy machinery and equipment often draw high currents, which can lead to overheating and damage. Contactors equipped with overload relays monitor the current flow and protect the system by tripping the circuit in case of excessive current, preventing costly breakdowns and ensuring the safety of both equipment and personnel. - Power Distribution:

Contactors act as key players in power distribution systems. They facilitate the efficient routing of electrical energy from the source to various loads. By selectively connecting and disconnecting different circuits, contactors enable the distribution of power to different areas or equipment, optimizing energy usage and enhancing overall system performance. - Automation and Control Systems:

In the era of automation, contactors find extensive use in control systems. They form an integral part of programmable logic controllers (PLCs) and other automated systems, allowing for remote control and monitoring of electrical devices. Contactors enable seamless integration with sensors, timers, and other control components, enabling precise and synchronized operation of complex industrial processes. - Safety and Emergency Shutdown:

Contactors play a crucial role in ensuring safety during emergencies. In critical situations, such as a power surge or a fault in the system, contactors can be programmed to instantly disconnect the power supply, preventing further damage or hazards. Their ability to rapidly interrupt the flow of electricity makes them indispensable in safeguarding both equipment and personnel.

Conclusion:

Contactors are the unsung heroes of the electrical world, silently orchestrating the flow of power and ensuring the smooth operation of various systems. From control and protection to power distribution and automation, their multifaceted functions make them indispensable in industries ranging from manufacturing and construction to transportation and energy. Understanding the capabilities of contactors empowers engineers and technicians to design robust and efficient electrical systems, paving the way for technological advancements and a safer, more connected world.