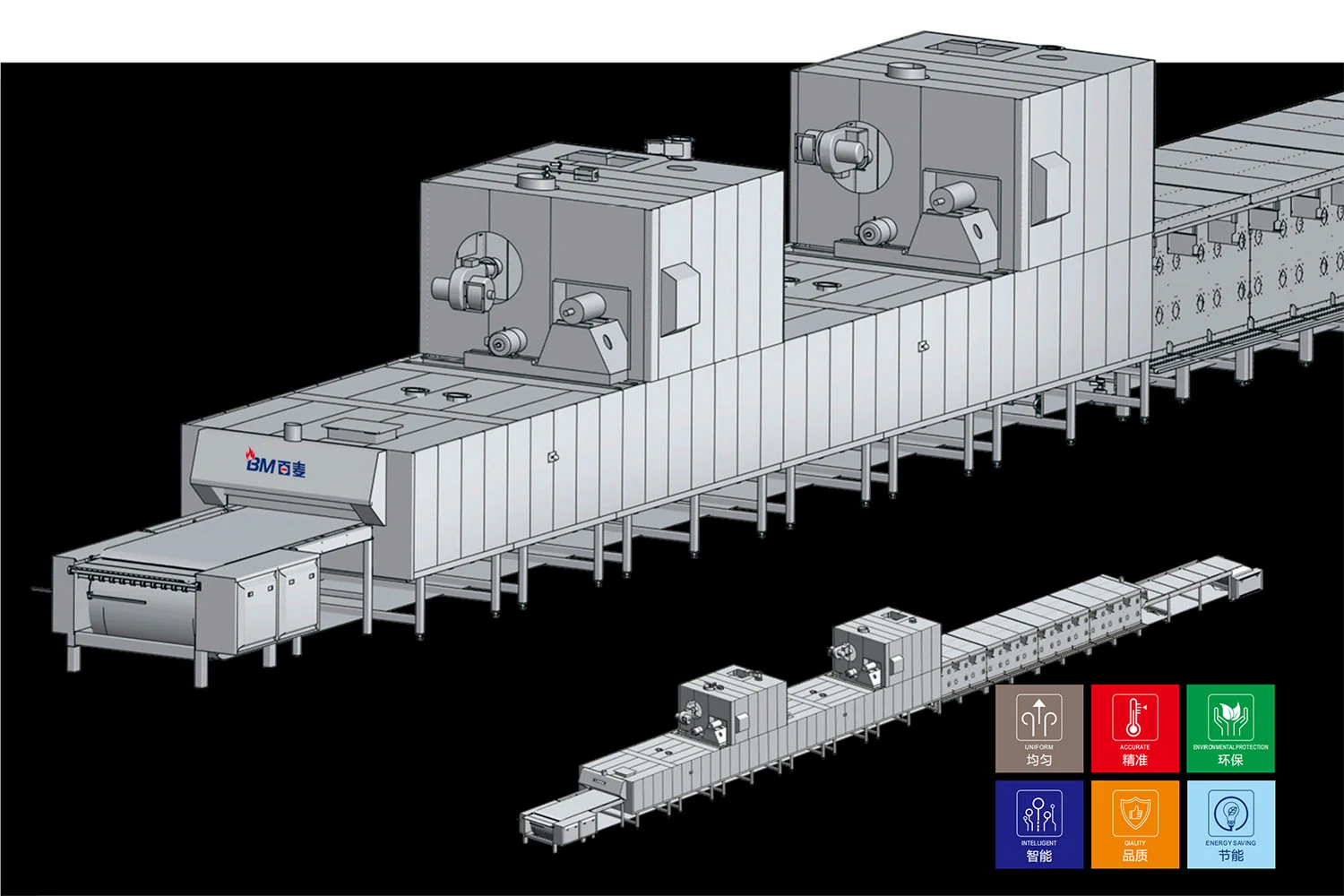

Advances in baking technology play a vital role in improving efficiency, quality, and consistency. In this blog post, Baimai, as a professional automated baking production line supplier, will share the advantages of industrial heat radiation tunnel oven for bread production, which improves large-scale bread production efficiency by providing excellent baking performance.

1. Enhanced Baking Efficiency

Industrial heat radiation tunnel ovens provide unparalleled efficiency in bread production. These ovens are designed to handle high volumes of bread continuously, allowing bakeries to scale up their production without compromising on quality. The continuous movement of the baking belt ensures a steady flow of bread through the oven, eliminating downtime between batches. This high throughput capability helps bakeries meet increasing market demands while maintaining operational efficiency.

2. Uniform Heat Distribution for Consistent Quality

One of the primary advantages of industrial heat radiation tunnel ovens is their ability to distribute heat evenly across the baking chamber. Unlike traditional convection ovens that may result in uneven baking, these tunnel ovens use radiant heat technology to ensure uniform temperature distribution. This even heat application prevents underbaking or overbaking, producing bread with consistent texture, crust, and color. The ability to maintain a uniform baking environment is critical for bakeries that prioritize product quality and consistency.

3. Energy Efficiency and Cost Savings

Energy efficiency is a major concern for commercial bakeries due to the high energy consumption of baking equipment. Industrial heat radiation tunnel ovens are designed with advanced insulation and optimized heat management systems, reducing energy waste. The precise control of heat radiation minimizes energy loss and lowers overall operating costs. Additionally, many modern tunnel ovens are equipped with heat recovery systems that recycle excess heat, further improving energy efficiency and reducing utility expenses.

4. Increased Production Capacity

For large-scale bakeries, meeting production demands efficiently is crucial. Industrial heat radiation tunnel ovens can process a significant number of bread loaves per hour, significantly increasing production capacity. The continuous baking process eliminates the need for manual handling of trays, reducing labor costs and production time. With the ability to bake more bread in less time, bakeries can expand their market reach and improve profitability.

5. Better Moisture Retention and Texture

Achieving the perfect texture and moisture level in bread is essential for customer satisfaction. Industrial heat radiation tunnel ovens provide controlled baking environments that help retain moisture in the dough, preventing excessive drying. This results in bread with a soft and fluffy interior while maintaining a crisp and golden crust. Consumers appreciate bread that stays fresher for longer, giving bakeries a competitive edge in the market.

6. Automated Control Systems for Precision Baking

Modern industrial heat radiation tunnel ovens come equipped with advanced control systems that allow bakers to fine-tune baking parameters with precision. These automated systems enable the adjustment of temperature, baking time, and humidity levels according to specific bread recipes. With programmable settings and real-time monitoring, bakeries can ensure consistent product quality while minimizing human error. The automation also enhances workplace safety by reducing the need for manual intervention in high-temperature environments.

7. Versatility in Bread Production

Industrial heat radiation tunnel ovens are designed to accommodate various types of bread and baked goods. Whether producing sandwich loaves, baguettes, artisan bread, or specialty bread, these ovens offer flexibility in baking different products with consistent results. The adaptability of tunnel ovens allows bakeries to diversify their product offerings and cater to different consumer preferences without investing in multiple baking systems.

8. Reduced Labor Costs and Improved Workflow

Traditional batch baking methods require significant labor for loading, unloading, and monitoring the baking process. Industrial heat radiation tunnel ovens streamline production by automating many of these tasks, reducing the need for extensive manual labor. The continuous baking process optimizes workflow efficiency, allowing employees to focus on other aspects of production, such as dough preparation and packaging. The reduction in labor costs translates to higher profit margins for bakeries.

9. Enhanced Hygiene and Food Safety Compliance

Maintaining hygiene standards is critical in food production, and industrial heat radiation tunnel ovens are designed to meet stringent food safety regulations. The enclosed baking environment minimizes contamination risks, and the stainless-steel construction of many tunnel ovens ensures easy cleaning and maintenance. Additionally, automated baking reduces human contact with the product, lowering the chances of contamination and ensuring compliance with food safety standards.

10. Long-Term Durability and Reliability

Investing in an industrial heat radiation tunnel oven is a long-term commitment that provides reliable performance for years. These ovens are built with durable materials and components that can withstand continuous high-temperature operation. Their robust construction minimizes the risk of breakdowns and costly repairs, ensuring uninterrupted production. With proper maintenance, bakeries can maximize the lifespan of their tunnel ovens, making them a cost-effective investment in the long run.

Conclusion

The advantages of industrial heat radiation tunnel ovens for bread production make them an indispensable asset for commercial bakeries. From enhanced efficiency and uniform heat distribution to energy savings and automation, these ovens provide a comprehensive solution for large-scale bread manufacturing. By adopting this advanced baking technology, bakeries can improve product quality, increase production capacity, and achieve greater profitability. As the demand for high-quality bread continues to grow, industrial heat radiation tunnel ovens will remain a key driver of success in the baking industry.

www.bmbaking.com

Baimai