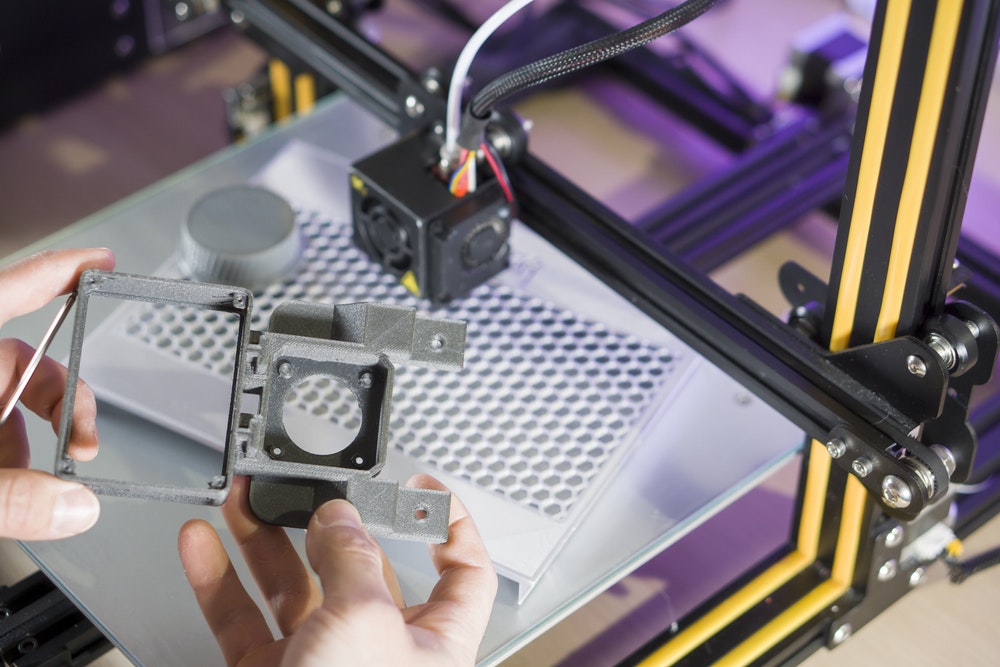

In the realm of modern printing technology, plastics play a pivotal role in the production of various printer components. From the sturdy outer casings to the intricate internal mechanisms, printers rely on specific types of plastics to ensure optimal performance and durability. In this article, we delve into the fascinating world of printer plastics, exploring the different types commonly used and their unique properties.

- ABS (Acrylonitrile Butadiene Styrene):

ABS is a widely employed thermoplastic polymer known for its exceptional strength and impact resistance. It is commonly used in printer casings due to its ability to withstand mechanical stress and protect the delicate internal components. ABS also exhibits good heat resistance, making it suitable for printers that generate significant heat during operation. - PLA (Polylactic Acid):

PLA, a biodegradable thermoplastic derived from renewable resources such as cornstarch or sugarcane, has gained popularity in recent years. While PLA is not as robust as ABS, it offers advantages in terms of environmental sustainability and ease of use. PLA is often used for printer filament, providing a more eco-friendly alternative to traditional plastics. - PETG (Polyethylene Terephthalate Glycol):

PETG is a versatile and durable thermoplastic that combines the properties of both ABS and PLA. It offers excellent impact resistance, chemical resistance, and transparency, making it suitable for various printer components. PETG is commonly used for printer enclosures, extruder parts, and filament spools. - Nylon (Polyamide):

Nylon is a strong and flexible synthetic polymer that finds application in various industries, including 3D printing. Its low friction coefficient and high tensile strength make it ideal for printer gears, belts, and other moving parts. Nylon also exhibits good resistance to chemicals and abrasion, ensuring longevity in demanding printing environments. - PC (Polycarbonate):

Polycarbonate is a robust and transparent thermoplastic known for its exceptional impact resistance and heat tolerance. It is commonly used in printer components that require high strength and clarity, such as printer windows, display screens, and protective covers. PC's ability to withstand high temperatures without deformation makes it suitable for printers with heated beds.

Conclusion:

As we've explored the diverse world of plastics used in printers, it becomes evident that each type offers unique properties and advantages. From the strength and impact resistance of ABS to the eco-friendliness of PLA, printer manufacturers carefully select the appropriate plastics to ensure optimal performance and longevity. Understanding the different types of plastics used in printers allows users to make informed decisions when purchasing or maintaining their printing equipment.